Harvest time brings forth a wave of anticipation for good reasons. It marks the moment when the nurtured buds reach their full maturity, requiring careful shepherding from the harvest to the shelf. The post-harvest quality of the flower hinges on a meticulous approach, ensuring every detail is preserved. Taking a moment to delve into our harvest process, I’d like to outline some of the crucial steps we undertake to guarantee the excellence of each flower bud in our jars.

In our recent harvest, we gathered Super Chief, Purple Blossom, Gelato 33, and Julius Caesar, all of which stand as exceptional representatives of their cultivar, truly the best in class.

Our journey to deliver this unparalleled quality begins with a process of careful selection. Our Large Bud Eighths consist solely of the top colas from each plant, the ones that have received the most resources. We start by cutting down samples that represent the overall harvest, examining them closely under our Celestron microscope. Our focus is on ensuring that the trichomes are fully mature and developed. Once we confirm the plants meet our specifications, we meticulously prune the branches. Unlike conventional methods that involve cutting down the entire plant at once, we selectively remove the finest branches, ensuring that only the absolute best make their way into our eighth jars.

Each branch is scrutinized, evaluating the maturity and integrity of the buds. Our aim is to select densely stacked flower buds with no discernible gaps in their structure. These pristine cuts are then sent to the trim room, where each bud undergoes a detailed styling process.

The first task upon the branch’s arrival in the trim room is the swift removal of large fan leaves while the buds remain on the branch. This process exposes the delicate flowers underneath and streamlines the trimming process for the next phase. Our de-leafing crew will diligently mow through branch after branch feeding the waiting assembly line.

The flower is passed from the de-leafing crew to the manicure trim crew who carefully remove any excess non-resinated leaves. This meticulous process of styling the buds is what really brings out the definition of the bud structure. Once hidden pistils and calyces are now pronounced and add vibrance to the already beautiful flower.

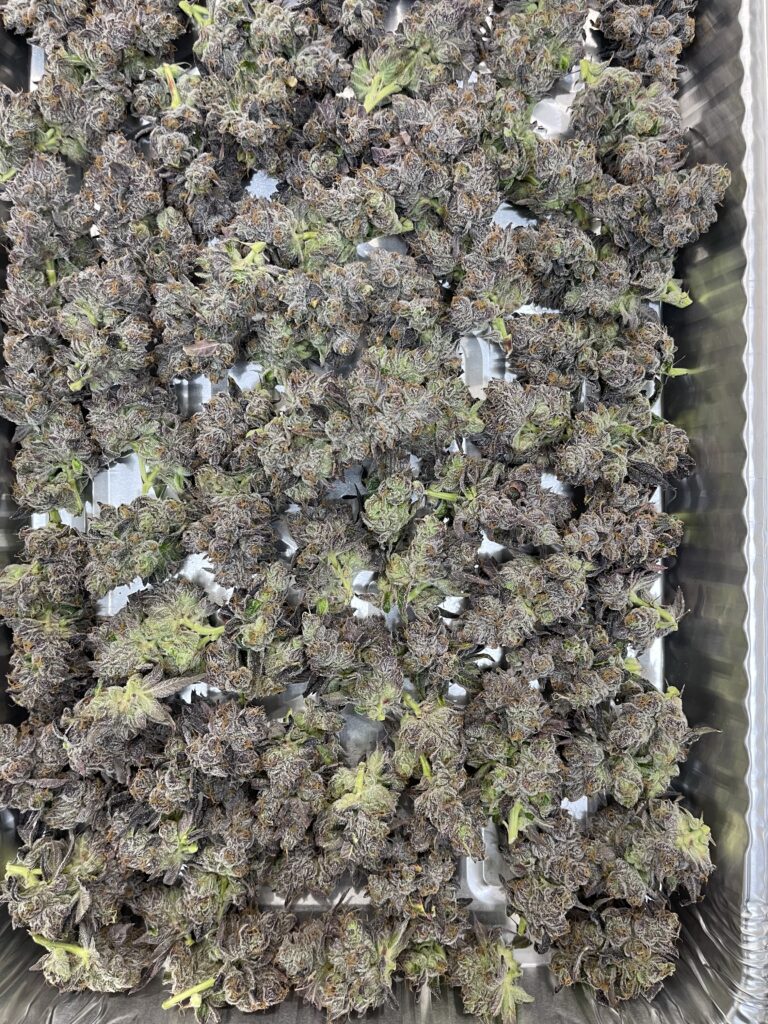

After achieving the ideal trim for the flower buds, we initiate the bucking process, where we delicately sever the buds from the main stem. These loose buds are then meticulously categorized into three containers based on their size: large, medium, and small. This grading system streamlines our packing process during harvest. Moreover, the separation of buds by size proves advantageous for our subsequent step – the finale.

The loose buds, sorted according to size, are thoughtfully placed on metal trays ensuring minimal contact between each bud. These trays are then sealed with metal lids to safeguard the delicate flower buds within. The next step involves rapidly freezing the sealed metal containers using dry ice and liquid nitrogen. This rapid freezing technique effectively suspends the flowers in time, halting any water movement within the plant and preventing any degradation. The frozen flowers are then transferred to a mobile freezer for transportation back to our facility.

Within a mere two hours of cutting down each branch, our team hand-trims, bucks, and freezes the buds. This strict timeline is crucial to maintain the flowers in their pristine state. Since cannabis is at its peak during harvest, our goal is to deliver this perfection to you. We hope that our diligent efforts shine through in the final product we offer.

To find some of our finished work, check out the retailers section of our site or visit our online store.

Stay safe and stay stoned!